Flare time or maybe not

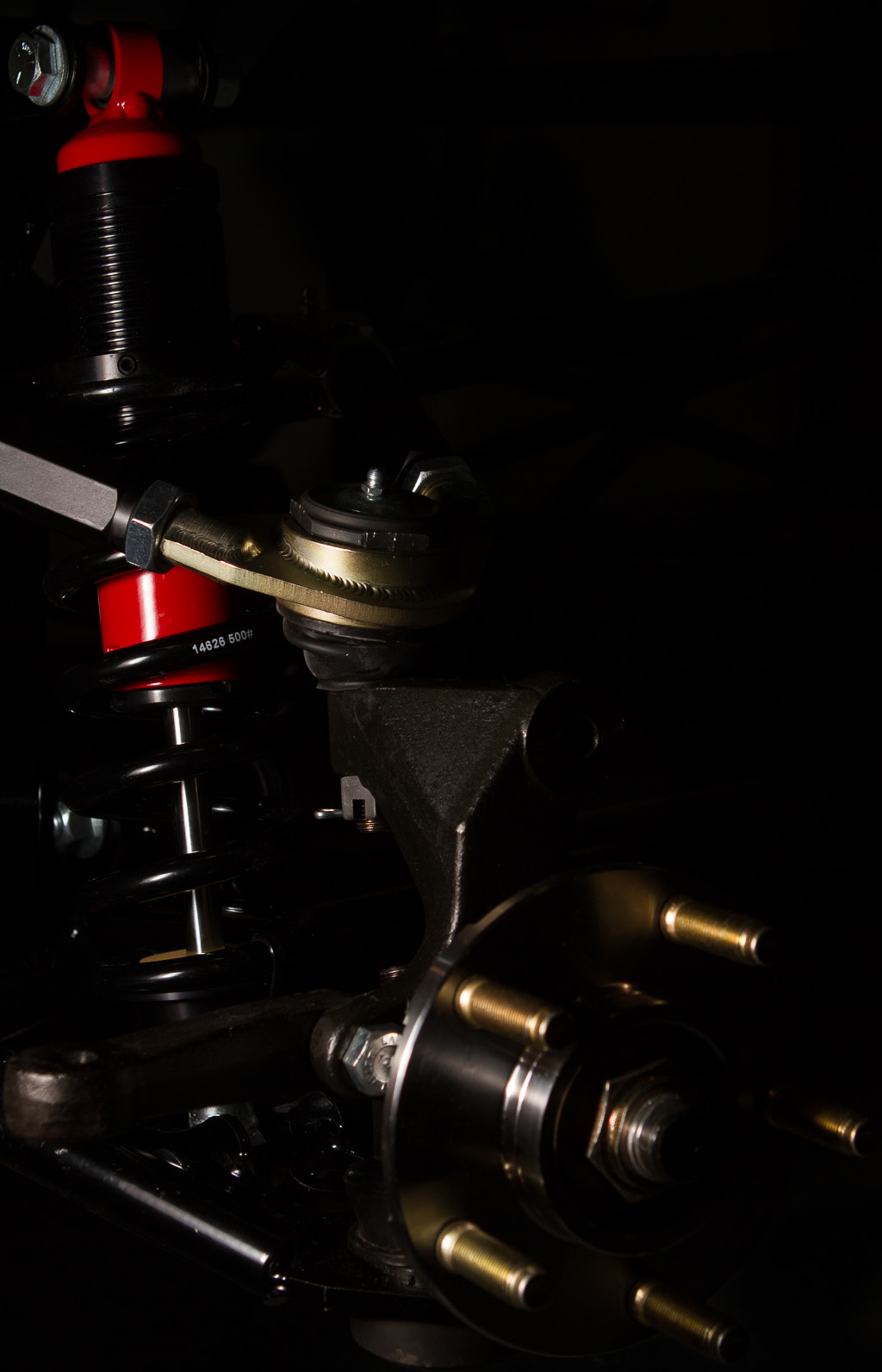

Well this weekend I was looking forward to finally getting to start to run the fuel and brake lines. Most of the stuff I need has arrived, fittings, tubing, adapters and the flaring tool. I already have a flaring tool but since I’m running Stainless Steel lines I needed a tool that was able to handle the harder stainless lines. To make things more complicated there are really 2 main options when it comes to flares. There is the double inverted 45° flares which you will find on just about every production vehicle. And then there is the 37º AN type flare, you will find these on aircraft and in the car world they are the red and blue fittings used with stainless steel braided hoses that you see on many hotrods. The pic below is an example.

For the trivia buffs the AN refers to Aeronautical Navy and the specs for these fittings were developed during WWII to provide a standard for aircraft tubing and hose fittings.

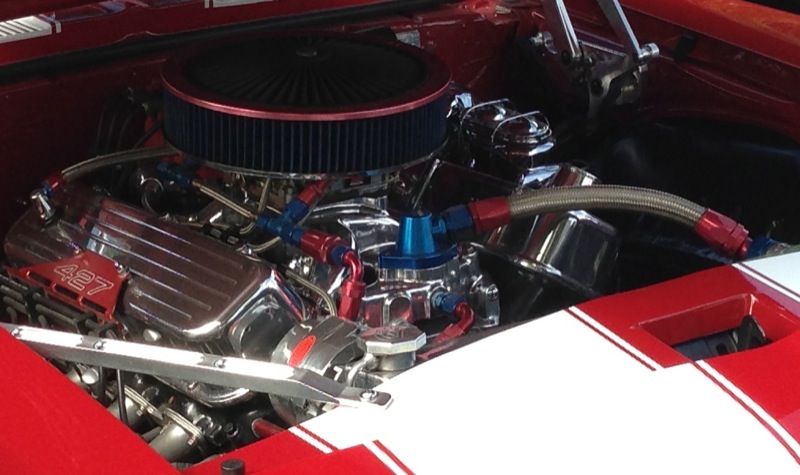

I decided I would go with the 45º inverted flare for all of the fuel and brake tubing. This would actually keep things a little bit simpler and I would just use adapters on the fuel lines to transition from the 45º flare to the AN -6 fittings. Also, this way I would only need one flaring tool. And by keeping the brakes at the 45º flare standard off the shelf auto repair stuff will work with it. BTW the -6 refers to the size of the hose and it’s in increments of 1/16 inch. So a -6 hose is 6/16 or 3/8.

I ordered a new flaring tool from the same company I ordered the stainless tubing and fittings. I ordered a flaring tool that clearly states on the website it is for steel and stainless steel tubing. See where this is going? Flaring tubing for a 45º inverted flare is a 2 step process. First you use a die that compresses the end of the tubing in and then in step 2 you use the point of the flaring tool to fold that same area over while at the same time flaring out the end of the tube.

In the pic below you can see a completed flare and you can see the folded over portion in the flare. The inside of the tube is a copper color and you just see a portion of that in the center of the tube and the steel lip folded over into the flare. The flare is at 45º to the tubing. I hope all that makes sense. In a future post I will post pics of each stage of the flaring. I didn’t do this flare, this is one that came with the car but as you see it’s an ugly green tube not nearly as pretty as the stainless tubing.

So now the sad part or more appropriately I should say the pissed me off part. On the very first flare the die for step one cracked before I even got halfway flaring the tubing. So much for using it on stainless. You can be sure the company will be hearing from me on Monday.

Dude,

You are going to have fun, very time consuming to make them correctly. Way back when I always hated them. Good luck.

Hey Randy, I have a couple of those dies for double flares if you want to borrow one.

Let me know and can bring it in to the office.

Tom

Tom, Thanks for the offer but this flaring set is going back to the seller and I’ve already ordered a different tool. After doing some research it seems the one from Eastwood is what everyone says does a perfect job on stainless each time. I found one on sale on ebay so I should be good.

Sounds like you are still enjoying the process, even though the”flare thing” raised your blood pressure.

Keep the updates coming!

Cheers.

The “pissed off” part, is that the relaxation thing Randy keeps talking about, you know how it helps him “relax” after a stressful week?

Keep the updates coming!

Richard

Yea it’s a different kind of “pissed off” one that I have a bit more control over so it’s all good. Turns out after talking to the company I bought the tool from and speaking with their sales manager, they offered to replace the button for free. I told him I wasn’t satisfied with the tool and had already ordered a replacement. He said no problem, issued me a RMA and is refunding my money. So I’m happy about that.

Randy, I have an old double flare Kit that I picked up the “70s” (cost me somewhere around 60 or 70 dollars)when I restored my “66 Mustang” real heavy duty and still have all the parts. worked great on the steel break lines. If you want I will give it to you, just let me know.

Terry thanks but I already bought a double flare tool that works on stainless used it quite a bit this weekend.

No problem Randy, just wanted to offer. The build is looking real good.